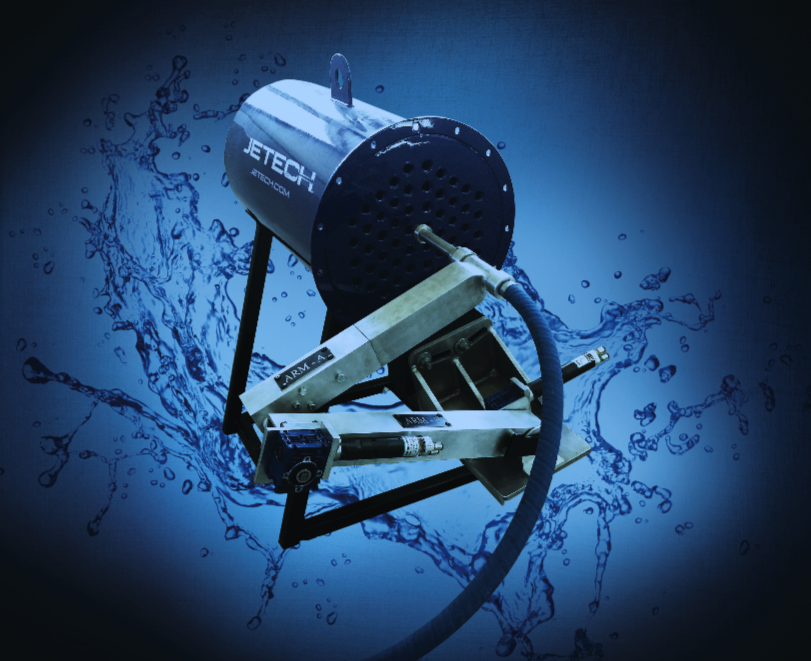

Using High-Pressure Water Jetting Equipment from Jetech to Prepare Surfaces

One of the most common uses of Jetech’s high-pressure water jetting equipment is the preparation of surfaces. Often, when tasked with reworking an old surface, the first step is the removal of rust, paint, corrosion, and previous powder coatings. When this is the case, many people – out of instinct – turn to sandblasting because they are unaware that water jetting is a cleaner, more economical, and more environmentally friendly option. Whether you’re restoring an old building, bringing a manufacturing facility up to standards, or putting a new face on an old commercial complex, you can be confident that water jetting the old surfaces is a great place to start. In today’s post, we’re going to look at a few of the benefits of using our high-pressure water jetting equipment.

Cost-effective

Compared to other surface preparation methods, water jetting is a more economical solution. Beyond reduced equipment costs, water jetting also keeps labor costs lower as it doesn’t require intensive cleaning.

Cleaner and less intrusive

When sandblasting, you’re left with a large volume of dirt and dust, which requires a lengthy cleanup process after the job is done. As water jetting only expels water vapor, you reduce the amount of time and labor necessary to complete the job.

Multiple applications

High-pressure water jetting equipment can be used to prepare a wide range of surfaces, from small parts to large vertical surfaces. Whether you’re preparing a component for production or you’re stripping the paint from a wall, you can be confident that Jetech’s equipment can rise to the challenge.

At Jetech, we strive to provide our customers with the most economical and effective surface preparation equipment on the market. If you’ve been searching for a way to strip paint, remove rust, or undo a bad powder coating, contact us today to discuss how we can help.