Subsea Pumps

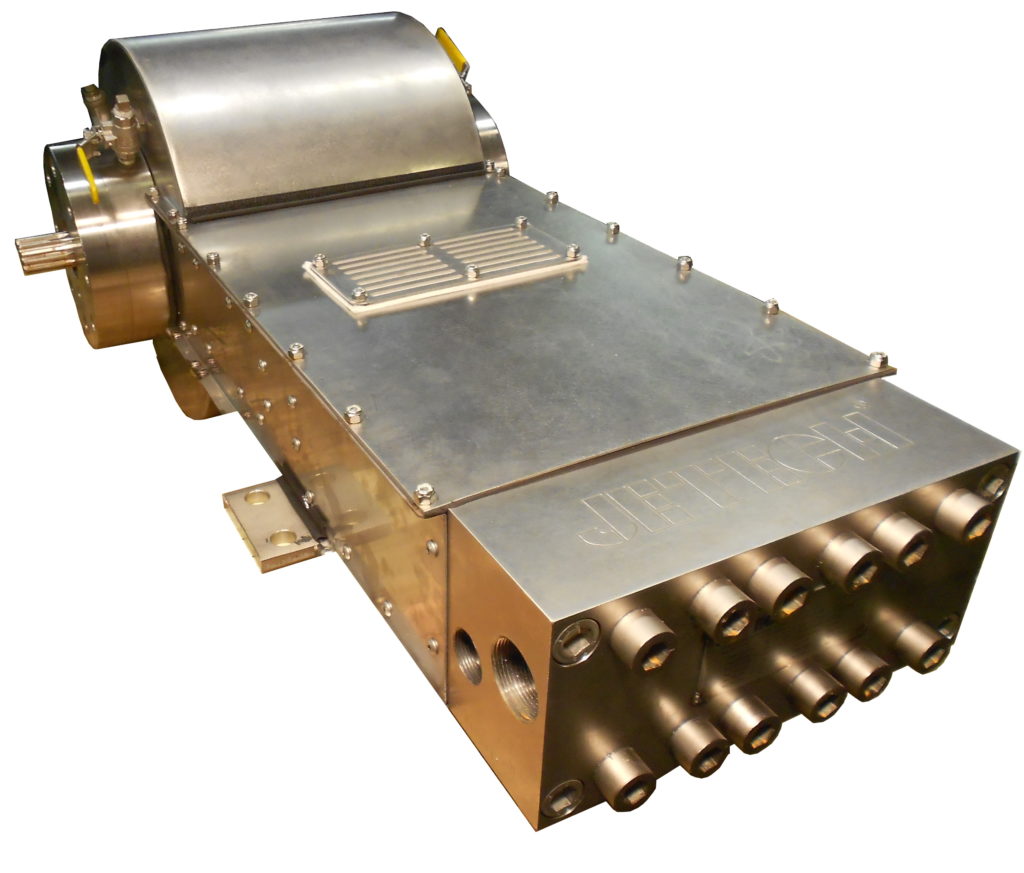

XP-UW 100J3 Subsea Pumps

Jetech's industrial submersible XP-UW Subsea Pump is the world's only open-frame submersible plunger pump for infinite depths.

Without a doubt, Jetech's XP-UW 100J3 Subsea Ultra-High Pressure triplex pumps embody a new era in underwater pumping equipment. Engineered to function in sub-sea environments, the pumps operate up to 40,000 PSI (2,750 bar) discharge pressure.

Engineered to operate using seawater for cooling and lubricating the bearings and other moving components, the XP-UW 100J3 pumps do not require oil or grease in the power-end

Manufactured in sizes up to 700 horsepower, the high-pressure submersible pumps have a proven track record of deep-sea dives and are designed to operate in underwater depths of 10,000 feet or more.

Reduced Tubing Costs and Pressure Issues

Mounting the subsea pump to a remote operating vehicle eliminates thousands of dollars in expensive ultra-high pressure hose, with savings in excess of $100,000 dollars depending on the depth. In addition, mounting requires only about 20 feet of hose, resulting in the following:

- Elimination of the excessive pressure drops associated with long lengths of the hose

- All pressure produced by the submersible pump completes productive work

- Increase in the efficiency of the water jetting process.

The unique design of the submersible pumps permits the flooding of the crankcase with seawater, resulting in zero differential pressure between the internal and external casing of the power-end. The flooded crankcase allows the underwater pumps to operate in the deepest depths of the ocean.

Compatible with a direct-connected hydraulic motor, Jetech offers the option of a right- or left-hand driveshaft.

Long-Lasting Construction

The all-stainless steel construction of the submersible pump (including the power end) resists seawater corrosion.

The main and connecting rod bearings are designed and manufactured from non-metallic, IOS-3000 material.

All the tie bolts are stainless steel or nickel coated to help prevent rusting and corrosion.

Applications

- Hydrostatic testing

- Subsea Hydrotest

- Blow Out Preventer (BOP) testing

- Methanol injection

- Pipeline lining/coating removal

- Precommissioning services

- Remote Operated Vehicle (ROV)

- Pipeline lining/coating removal

- Submersible vehicles

- Reverse Osmosis