ITC-G2 INTERNAL TANK CLEANING SYSTEM

Its Simple. It Blasts. It Lasts.

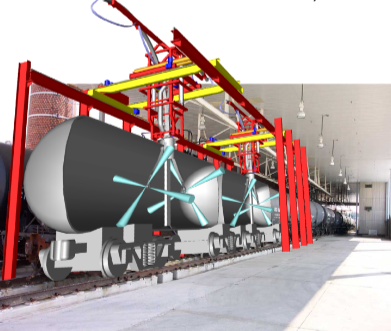

The new Jetech ITC-G2 Internal Tank Cleaning system is the latest, complete tank/vessel cleaning system designed for horizontal rail and mobile tank systems. This revolutionary design removes the need to send a person into the tank, which eliminates the danger associated with this type of job. The Jetech ITC-G2 features a new look and the new features you have been asking for.

ITC-G2 INTERNAL TANK CLEANING SYSTEM

- Safety: As always, the goal of the ITC systems have been to reduce or eliminate workers exposure to these vessels, and now Jetech has taken the process to a new level with advanced automation, combined processes, and amazing speed.

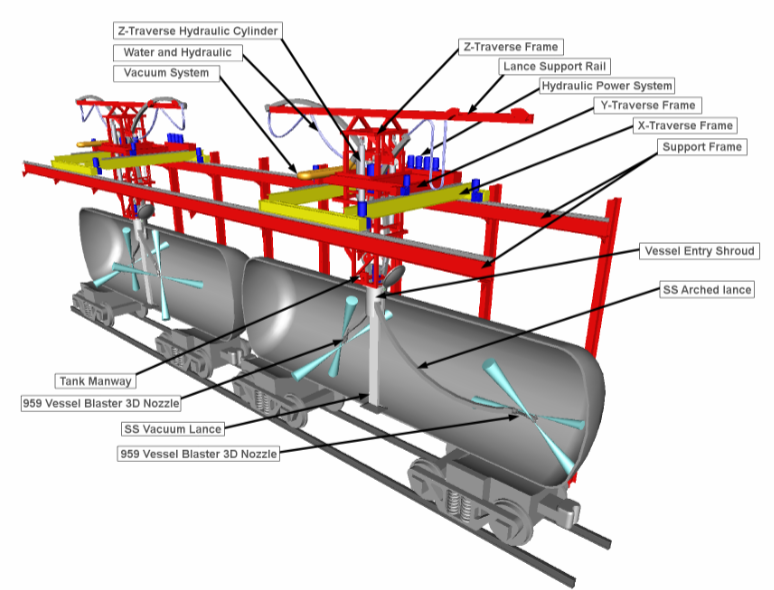

- Convenience: ITC-G2 is installed into position over the tank car rail system, supported on an elevated rail platform similar to an industrial bridge crane system.

- Extreme Pressure and Flow Capacities: High pressure water (or other liquid) up to 20,000 psi (1380 bar) and flow rates to 200 gpm (760 l/m) are used to thoroughly scrub the internal walls and structure of the vessel.

- Accessibility: Designed for horizontal, top-access tanks, only a manway is needed for the ITC-G2’s deep-reaching cleaning heads to enter the tank.

- Speed: The standard system features twin lances that can simultaneously or independently clean both sides adjacent to the manway. Cleaning cycle times can be as short as 5 minutes.

- Serious Coverage: Unlike other systems, the ITC-G2’s dual cleaning lances protrude deep into the tank and are capable of stopping only inches from the tank ends, which can be the most difficult areas to clean.

- Advanced Cleaning Technology: Each lance uses the Jetech model 959 three dimensional cleaning swivels. The 959 is the only positively driven (hydraulic is standard) with an externally controlled speed in the industry.

- Operator convenience: The ITC-G2 is remotely controlled and can travel in the X plane (parallel to the tank centerline); the Y plane (perpendicular to the tank centerline) and the Z plane (vertical motion toward and away from the tank). The positioning of the system into the tank manway is assisted by an array of cameras (three cameras standard).

- Automation: Once the unit is in position, a pre-determined program is chosen depending on the tank type and contamination level. Programming parameters include (but not limited to); lance speeds at different points in the tank, water pressure and flow rate, penetration depths, pump system control, vacuum lance positioning, and vacuum system control.

- The Pump: The Jetech pumping systems are the cleaning force behind the water jets. Electric or diesel driven high-pressure pump units are positioned near the ITC-G2 tank cleaning system and supply the high-pressure water. As small as a single 250 hp unit could be set up to feed one to three ITC-G2 systems for low cost/ low production area. For high production, several pump units (up to 600 HP each) can be combined, providing the highest cleaning rates in the industry.

- Waste Recovery: The vacuum wastewater removal system is the third key element to the ITC-G2. This system removes the standing water, wash waste, and fumes from the vessel as the cleaning occurs. Customized filters and scrubbers can be integrated into the system depending on the customer’s needs. Jetech works closely with the customer to create an efficient and safe waste removal system.

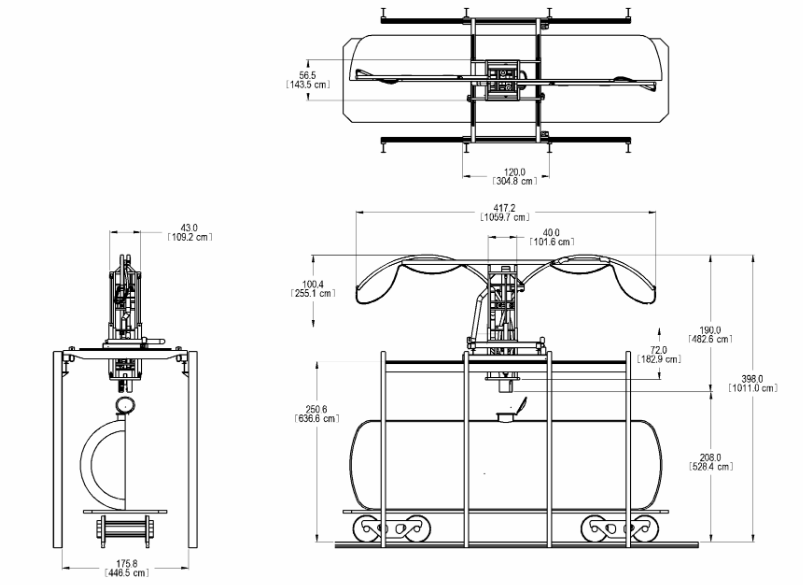

ITC-G2 Dimensions

The ITC-G2 is designed around US and international standardized mobile tank systems. The system will fit into some of the smallest manways in the industry. Too big, or too small? No problem, Jetech can easily customize the system to fit your dimensional needs

Jetech ITC-G2 Basic Dimensional Layout

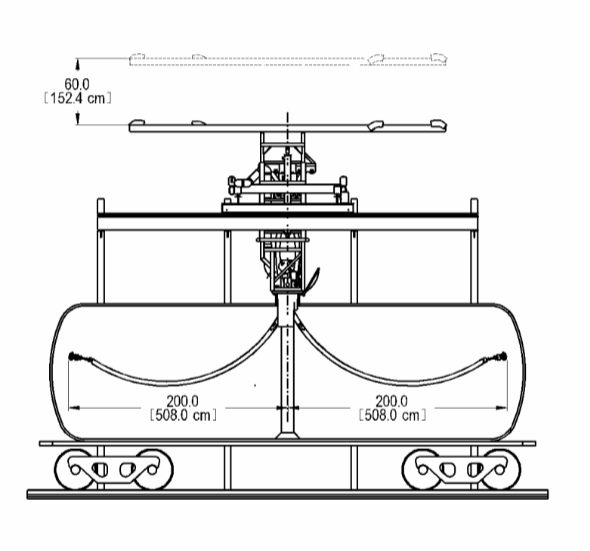

Jetech ITC-G2 Movement Envelope