3/10/2015

We have worked hard to increase safety and reduce workers’ exposure to the vessels while improving the efficiency of cleaning tanks with the control and flexibility that you need.

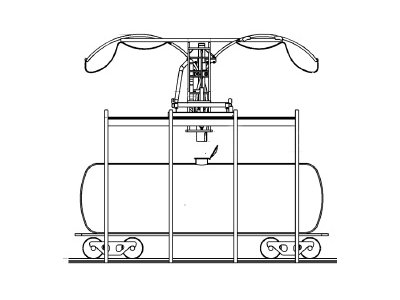

The new Jetech ITC-G2 is designed to position over a tank car rail system and supported on an elevated rail platform, similar to an industrial bridge crane system. Designed for horizontal, top-access tanks, all the tank/vessel needs is a manway for the cleaning system to enter the tank. The component fits even some of the smallest manways and can be made customizable if you feel it won’t fit to your tank.

Workers will no longer have to enter the tank for cleaning. The ITC-G2 is remotely controlled, and an array of cameras helps position it. It can move both parallel and perpendicular to the tank center line and in a vertical motion toward or away from the tank.

The twin lances are able to extend deep into the tank to reach even those hard to clean places. They can work either simultaneously or independently at different speeds and pressures, increasing efficiency and reducing the cleaning cycle time down to as short as 5 minutes. Each lance uses the Jetech model 959 three-dimensional cleaning swivels, the only positively driven with externally controlled speed in the industry.

Once it is in position, a pre-determined program is chosen based on your tank type and contamination level, adjusting the lance speeds, water pressure, flow rate, penetration depth, pump control system, vacuum lance positioning, and vacuum system control. All of this is done by the touch-screen main control panel.

The pump is the cleaning force behind the system. You can use either electric or diesel driven pumps, using a 250 hp unit for smaller production or combining several pumps for larger production, up to 600 hp each. The water, or other cleaning liquid, is high pressure at up to 20,000 psi (1380 bar) and flow rates up to 200 gpm (760 l/m).

Finally, vacuum waste water removal system removes the standing water, wash waste, and fumes from the vessel. We can customize it with custom filters and scrubbers if preferred. We work closely with you to create an efficient and safe waste removal system.

The Internal Tank Cleaning system keeps a history log of all the information, and you can access it to see past cleaning rates, cycle times, problems encountered, and the number of tanks cleaned in a time period.

The ITC-G2 is designed and US and international standardized mobile tank system, but if there is a potential compatibility issue, we can easily customize the system to fit your dimensional needs. Get in contact with us today to discuss your options.